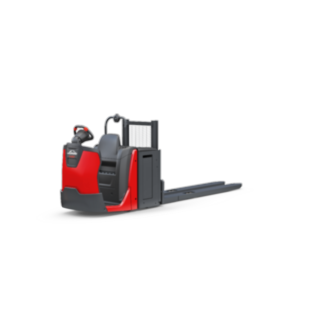

Simultaneous picking with two pallets at operator height

Thanks to its extra-long forks, the N20 XL from Linde Material Handling can transport two pallets on initial lift with a total weight of up to 1.6 t simultaneously. The mast construction allows the operator to load both pallets (300 kg each), at a height of 750 mm, making it easy on the operator’s back. As the operator platform is positioned in front of the battery, the operator always has a good view of the warehouse environment whilst operating the picker and can react early to dangerous situations. The entire operating platform is spring-loaded which reduces vibrations or shocks caused by uneven floors.

Characteristics

Safety

The N20 XL order picker has three braking systems that protect the operator and load: The electromagnetic service brake is coupled with a dead man’s switch and an emergency button. A hydraulically assisted braking system reduces the speed proportionally to the weight of the load, and the Linde brake control automatically applies when the drive control is released. Additional safety is provided by the flattened contours of the chassis and the rounded operator platform as well as the automatic lane centring of the Linde steering wheel. A steel bumper at the front of the truck reduces shocks and vibrations. A rubber coating can be added to the bumper as an option. When cornering, the truck reduces its speed in proportion to the angle of the steering wheel. As an option, LED front lights and the Linde BlueSpot™ also visually announce the order picker.

- Three separate braking systems

- Dead man’s switch and emergency button

- Flattened contours

- Automatic lane centring of the Linde steering wheel

- Automatic speed reduction when cornering

Ergonomics

The wide operator platform, which is easily accessible from both sides, has a low entrance which enables the operator to get on and off easily. Two pallets can be loaded simultaneously at a height that is easy on the back, thus saving unnecessary movement. To further optimise efficiency, the mast control and optional pedestrian controls for moving the truck are located on both sides of the backrest. The operator cab has various options for the operator to adapt the truck to their requirements, including many storage areas. Both the intuitive Linde steering wheel and the backrest with fold-out seat are height-adjustable to suit the operator. In addition, the operating platform is spring-loaded and reduces vibrations and shocks while operating.

- Wide and low access points

- Pedestrian controls on both sides of the backrest

- Storage areas in the operating platform

- Intuitive Linde steering wheel

- Suspended operating platform

Handling

Powered by a 3-kW three-phase AC motor, the order picker can quickly accelerate to up to 12 km/h (7.5 mph). Various wheel designs ensure truck and load stability on transport routes within the warehouse. The lead-acid or lithium-ion battery provides the optimum power supply to meet the requirements of the fleet. With the intuitive Linde steering wheel, the operator controls all driving and mast functions effortlessly and with pin-point accuracy. For very short distances in the rack rows, the operator can comfortably use the pedestrian function controls on both sides of the truck, saving unnecessary boarding and alighting. An initial lift function facilitates transport over ramps and uneven surfaces.

- 3-kW three-phase motor

- Choice of wheels for stability

- Lithium-ion battery (optional)

- Effortless control with the Linde steering wheel

- Pedestrian function

Service

The order picker has a low servicing requirement and runs for around 1,000 hours before a service check is required. The three-phase AC technology requires no servicing and there is no need to readjust the brakes. During servicing, the service technician can easily remove the cover to the motor compartment and easily reach the central components. All wiring harnesses and cables are clearly arranged for quick servicing. The service technician can conveniently read the truck data on their mobile device via a CAN bus connection. A robust cast steel bumper protects the spring-loaded operator platform and thus reduces collision damage.

- 1,000 operating hours before servicing

- Adjustment-free brakes

- Easy access to the engine compartment

- Cable harnesses and cables clearly arranged

- CAN-bus connection

Technical Data

| Model | Load capacity/Load | Lift | Travel speed, with/without load | Turning radius | Battery voltage/rated capacity (5h) |

|---|---|---|---|---|---|

| N20 XL | 0.6 / 1.6 (t) | 750 (mm) | 10 / 12 km/h | 2466 / 2536 (mm) | 24 / 375 (V)/(Ah) o. kWh |

Optional Equipment

-

Linde fleet management

-

Load backrest

-

Linde BlueSpot™

-

Lithium-ion battery

-

Pedestrian controls

-

Lateral battery change

-

Bumper

-

Fully suspended operating platform

Linde fleet management

The fleet management system from Linde is used to manage the truck fleet. From maintenance scheduling to documentation of the maintenance and repair history through to access control.

Load backrest

The load backrest, which can be adapted to the height of the load, provides additional protection for the operator and load.

Linde BlueSpot™

The Linde BlueSpot™ route warning system increases safety in operation, as the LED spot makes trucks silently visible.

Lithium-ion battery

With Linde’s innovative lithium-ion technology, trucks can be recharged in a much shorter time and interim charging can be carried out during operation, increasing the availability of the trucks.

Pedestrian controls

There are push buttons on both sides of the truck that the operator can use to operate the order picker from outside the truck and walk alongside it at the same time.

Lateral battery change

The lateral battery removal by means of roller bearings enables a quick change, especially for use in multi-shift applications.

Bumper

The bumper reduces shocks in the event of a collision, thus protecting operator, truck and infrastructure such as racks.

Fully suspended operating platform

The bottom of the platform, the steering wheel and the backrest, including the fold-out seat, are protected against vibrations and shocks.