Tugger trains from Linde Material Handling

Always providing the perfect solution

In modern industrial production, material supply must be precisely coordinated with the work cycles of the production machines and assembly lines. To ensure a synchronised and continuous material flow, it is crucial that the required materials are delivered to the right place (just in sequence) at the right time (just in time). This often requires the use of several intralogistics trucks at the same time, which in turn means higher investment and follow-up costs as well as an increased risk of accidents.

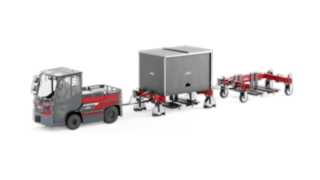

This is where the tugger train comes into play. It consists of a towing vehicle with one or more trailers. The different trailer types allow a variety of goods to be transported simultaneously using a single tugger train. The trailers are characterised by high directional stability, which allows the train to be driven precisely and reliably.

Our tugger trains at a glance

Linde Material Handling offers three different tugger train solutions, each optimised for their specific application. With their compact, single-axle design, the LT06 – LT10 M and LT10 W logistic train trailers are ideal for transporting goods indoors. Their robust construction and large outdoor tyres make the LT16 Ch/BMh trailers the perfect solution for transporting goods outdoors. As all-rounders, the LT10 – LT20 C and LT10 – LT16 B/BM models can be used both indoors and outdoors, offering maximum flexibility and versatility.

With a transport capacity of up to 2000 kilograms per trailer, a Linde tugger train enables the fast and reliable transport of large quantities of goods. The logistic trains impress with their excellent driving characteristics, boasting directional stability and high manoeuvrability. Thanks to their high level of efficiency in transporting goods, they minimise the volume of traffic, which sustainably reduces energy consumption and consequently saves costs and protects the environment.

All in all, this makes tugger trains one of the most economical, safest and most environmentally friendly solutions for the indoor transportation of goods. With its logistic trains, Linde offers solutions individually tailored to customer requirements to make the transport of materials over short, medium and long distances as efficient and flexible as possible.

A tugger train for all occasions

Indoor train

The indoor train consists of the trailers LT06 – LT10 M and LT10 W. It is mainly used for the internal transport of raw materials from the warehouse to the assembly lines within a hall. Thanks to its compact design, it can be easily integrated into existing buildings and production layouts. In combination with the P60C tractor, this logistic train is the ideal solution for internal transport with trailers.

Outdoor train

With their robust two-axle construction and large outdoor tyres, the LT16 Ch/BMh tugger train trailers are designed for long distances outdoors. Together with the P250 tow tractor, this logistic train can cope with even the most difficult ground conditions, making it ideal for outdoor operations.

All-rounder

The LT10 – LT20 C and LT10 – LT16 B/BM trailers offer maximum versatility and flexibility for internal material flows. Indoors or outdoors: in combination with the P80 tow tractor, this tugger train is the perfect solution for larger loads that need to be transported within or between different factory halls.

Tugger train from Linde: load capacity meets versatility

Linde tugger trains are particularly versatile, as their small turning circle allows them to operate very precisely even in the tightest spaces. At the same time, they offer enormous flexibility when it comes to adapting the trailer modules to different types of transported goods, from pallets and pallet cages to special containers. The load is always on a trolley, which is pushed into the frame for fast goods transport and then lifted. Due to the ease of loading and unloading, tugger trains can transport more goods to workplaces or warehouses in less time than with single transports. The efficient transport of large quantities of goods means that they are profitable from a distance of 160 metres.

Features

Safety

Linde tugger trains are equipped with a variety of functions to ensure safe operation and operator protection. An automatic start interlock prevents the logistic train from accidentally moving with the loading frame lowered. While operating, the trailer’s lowering mechanism is automatically deactivated. In addition, the loading frames have a patented load securing system to reliably secure all transported goods. To avoid accidents, Linde Curve Assist automatically adjusts the speed of the truck when cornering. The safety of the tugger train can be further optimised with equipment options such as safety flags, different types of lighting and weather protection.

Ergonomics

For maximum ease of use and minimum physical strain, a Linde tugger train is optimised for ergonomic operation. Most loading frames can be loaded and unloaded at ground level. This protects the user’s back, as heavy goods do not have to be lifted, resulting in a reduced risk of injury and downtime. The loading frames are locked intuitively and automatically. The unlocking mechanism is mounted at an ergonomic height and can be conveniently operated with the foot. Some loading frames (e.g., C frame, M frame) have an ergonomic ejection mechanism that pushes the load away from the back of the fork as soon as the operator releases the lock.

Handling

The Linde tugger trains enable optimum handling performance both indoors and outdoors. Small turning circles, directional stability, tipping stability and high lifting speeds guarantee fast and safe transportation in any environment. Trailers for indoor use are single-axle to enable maximum manoeuvrability and dynamic driving manoeuvres. The low weight of the trailer allows the towing vehicle to cover distances at higher speeds. Trailers with a stable two-axle design and four-wheel steering are available for outdoor use (or for transport between halls). The loading frames are raised and lowered automatically for quick and easy load handling: When the operator gets into the towing vehicle, the frames are raised for transport. When they leave the truck, these are lowered again. The trailers are partially equipped with positioning aids, which enable smooth loading and unloading, making the trolleys easy to manoeuvre. Trailers that can be loaded and unloaded from both sides provide maximum flexibility.

Servicing

A Linde tugger train is characterised by high availability and low maintenance requirements. Thanks to the synchronised maintenance intervals of the towing vehicle and loading frame, maintenance work can be planned and executed in a time-saving manner. The frame design consists of only a few parts, which significantly reduces service costs. A mechanical locking mechanism ensures ease of service and facilitates maintenance and repair work. In addition, the tiller system of the trains is low-maintenance, which also saves time and costs.

Connectivity

Modern industrial production requires optimal coordination of material flows. Linde supports integration into digitally controlled processes with the company’s own tugger train guidance system, Linde Logistic Train Controller, if required. This system enables the seamless integration of an automated tugger train, resulting in even more efficient connectivity of production processes. It coordinates the driving orders and provides the drivers with optimal routes. Standardised interfaces allow the loading frames to be equipped with automated tow tractors .

An overview of the advantages of a tugger train

A tugger train made to measure

Specialisation makes all the difference. This is why a Linde tugger train can be adapted to suit specific requirements. Be it pallet cages, pallets or other load carriers – suitable solutions are available for every type and quantity of goods. There are also many additional features available, including weather protection for the various trailer modules, different tyre options and special lighting options. It is also easy to customise the colour of the tugger trains. If customers do not want the classic Linde red, they can opt for a special paint finish.

FAQ – Frequently Asked Questions about tugger trains

What are tugger trains and where are they used?

A tugger train (also known as a logistics train, trailer train or load train) is an internal means of transport that is mainly used in intralogistics processes, primarily in manufacturing companies. It is used to regularly cover longer distances within a company and to transport material in bundled form. Tugger trains usually consist of a towing vehicle and one or more trailers, into which trolleys are pushed for transport. They are used to supply materials to the different sections of a production facility.

What types of goods can tugger trains transport?

Tugger trains are often used to transport materials within a production facility. These can be raw materials, semi-finished products or finished products. These products can be placed on a wide variety of load carriers, such as pallets, pallet cages or crates, which in turn are placed on a trolley. In some cases, tugger trains are also used to move tools, machines or other equipment within a facility or to deliver components and parts to production.

Are tugger trains energy efficient?

Tugger trains can be considered energy efficient. As a rule, they are used for ground-level material transport and can optimise and automate the movement of goods within the company. By efficiently planning and controlling the tugger trains, unnecessary routes can be avoided and energy consumption can be reduced.

What type of power unit is used for tugger trains?

There are different types of power units for tugger trains. They can be equipped with an electric drive that offers high energy efficiency and low emissions. In some cases, tugger trains can also be equipped with a diesel engine or a hybrid drive, whereby the hybrid drive combines the advantages of electric and diesel drives. The type of power unit used in a tugger train can depend on various factors, such as the size of the train, the route and the specific requirements of the given application.

What are the advantages of using tugger trains for my company?

The use of tugger trains can bring a whole range of different benefits to a company. They enable the fast and efficient supply of materials to the various areas of a production facility, which can lead to an increase in productivity. A company can save costs by bundling supply and disposal processes. Depending on your requirements, tugger trains can be adapted to the specific application in question and are therefore flexible to use. They are particularly useful for the just-in-time supply of assembly lines. Here, they help to standardise synchronised processes. They also reduce the volume of transport compared to transporting goods individually and therefore ensure greater safety by reducing traffic.

Whom can I contact if I have problems with my Linde tugger train?

If you have problems with a Linde Material Handling tugger train, you can contact Linde customer service. The corresponding contact form can be found on the Linde website. Using the form, you can describe your concerns and request support. Alternatively, you can contact the dealer where you bought the tugger train.

What determines the price of a tugger train?

The price of a tugger train depends on a number of factors, such as the model selected and the equipment required. An important price factor is also the number of trailers. If tugger trains have to be customised for specific operations, this can also affect the final price. In addition, the towing vehicles must be equipped to work with a variety of trailers, for example to allow an electric or hydraulic lifting function.

Hire, buy or lease a tugger train

If you have found the right tugger train, we have the right financing model for you. Linde consultants will provide you with a comprehensive overview of all available options, whether you are looking to buy, hire or lease. Our experts are always on hand with their specialist knowledge to help you find the best financing solution for your tugger train.