E14 – E20 and Xi10 – Xi20 electric counterbalanced forklift trucks

The right forklift for every application

Counterbalanced forklift trucks are the backbone of intralogistics. They have become indispensable in warehouses, production facilities and logistics centres. In the payload range of 1 to 2 metric tons in particular, they handle a wide range of tasks around the globe. Choosing the right forklift will help to determine the efficiency, reliability and cost-effectiveness of your transport operations.

This is where the new E14 – E20 and Xi10 – Xi20 electric counterbalanced forklift trucks from Linde come into their own: the sheer variety of models available, unparalleled on the market, is combined with superior performance, outstanding safety and excellent ergonomics. This means that the forklift trucks in the segment up to 2 metric tons offer the maximum performance in every conceivable use and guarantee the highest level of cost-effectiveness.

Variety meets performance: Our models

Maximum variety, the perfect fit for any application

In the payload class of 1 to 2 metric tons, the E14 – E20 and Xi10 – Xi20 offer a uniquely varied range of models. The portfolio contains 26 model variants: thanks to the wide range of battery capacities, load capacity variants, chassis sizes and steering axles, the E14 – E20 and Xi10 – Xi20 offer the perfect setup for every application requirement. In addition, there are various energy options to choose from: proven lead-acid batteries, highly efficient Li-ION technology or innovative fuel cell systems.

Infinite possibilities: E14 – E20

The E14 – E20 are the ideal solution for tight environments in warehouses or production facilities. They combine a compact design and outstanding manoeuvrability with a top speed of up to 20 km/h. The E14 – E20 rely on a powerful 48 V electrical system that delivers an optimal ratio of performance, energy efficiency and cost-effectiveness. There are a total of 14 different model variants to choose from, which differ in terms of their load capacity, battery size, height and whether they are designed as the three-wheeled or four-wheeled version.

Ultimate flexibility also applies to the energy source: here, fleet operators can choose between the lead-acid batteries, Li-ION batteries and fuel cell systems offered by Linde. Thanks to the plug & play principle, they can continue to use existing batteries or switch between lead-acid and Li-ION batteries without having to convert. The side battery door also makes it easier to change the battery.

The master performer: Xi10 – Xi20

The Xi10 – Xi20 have been shown to be the highest-performing representatives of their payload class. In combination with a 90 V Li-ION battery and sophisticated heat management, they increase the efficiency of the drive and lift motors by up to 5 percent and thus guarantee full performance at all times, even in continuous operation. With lifting and lowering speeds around 20 percent above the industry average, the Xi10 - Xi20 set new standards in productivity.

A range of battery capacities up to 32 kWh enables the forklifts to be flexibly adapted to any operating conditions. Thanks to their robust design, they can also be used outdoors in the four-wheeled version with pendulum axle (Xi16 – Xi20 P only) without having to make any compromises. Altogether, the Xi10 – Xi20 are available in 12 different design variants.

The spacious miracle

The permanently integrated Li-ION battery of the Xi10 – Xi20 and the absence of a battery tray have allowed the workplace to be redesigned. In addition to the increased headroom, the footwell in particular has been significantly expanded and now offers the operator legroom that is a significant 35 percent greater than the industry average. The step was enlarged and lowered at the same time, so that it is now just 40 centimetres above the ground. This means that the Xi10 – Xi20 offers the lowest entry step in the industry and guarantees maximum comfort and safety when getting in and out of the truck.

The renowned trade journalist and forklift truck expert Theo Egberts carried out an extensive performance test, which confirmed the outstanding performance, speed and manoeuvrability of the Xi models. These results reinforce the status of the E14 – E20 and Xi10 – Xi20 as the world’s most powerful electric forklift trucks in their class and confirm that they are setting new standards for payloads up to two metric tons.

Which forklift truck is the model for you?

Indoors, outdoors and everywhere: The right axle for every situation

If you want to achieve maximum productivity and profitability, the general rule is that the better forklifts are tailored to your specific requirements, the more productive they are. That is why there are two different steering axle variants to choose from for the E14 – E20 and three different steering axle variants for the Xi10 – Xi20. These enable the forklift trucks to be perfectly matched to the ground conditions in industrial buildings and outdoor areas.

-

Indoor pro: Three-wheeled version with swivel steering axle

-

All-rounder: Four-wheeled version with combi-steering axle

-

Outdoor hero: Four-wheeled version with pendulum steering axle

Indoor pro: Three-wheeled version with swivel steering axle

Three-wheeled forklifts from Linde use the tried-and-tested swivel axle. The benefits of this axle variant come to the fore when it is used indoors. It performs particularly well in transport operations in tight spaces where maximum manoeuvrability is required.

All-rounder: Four-wheeled version with combi-steering axle

The combi-steering axle developed by Linde gives four-wheeled forklifts a degree of manoeuvrability approaching that of three-wheeled forklifts, but at the same time it helps to ensure maximum stability. This makes these forklifts ideal for use in indoor and outdoor areas.

Outdoor hero: Four-wheeled version with pendulum steering axle

The Linde pendulum axle is an established feature of Linde internal combustion forklift trucks. It combines a low centre of gravity with a robust design, also making it ideal for outdoor use, even on uneven ground (Xi models only).

Classic Linde

Ergonomics: Comfort for maximum productivity

The operator’s well-being has a decisive impact on their productivity. It is for that reason that the E14 – E20 and Xi10 – Xi20 offer a level of comfort and user-friendliness previously only seen in IC trucks. The mast, drive axle and steering axle are decoupled from the chassis by elastomer ring bearings to ensure stress-free work. This improves shock absorption and protects the operator when driving over uneven surfaces.

The ergonomic layout of the control elements, the spacious cab with improved cooling and heating performance, and the intuitive operation also help to minimise the physical strain on the operator. The operator’s cab has been kept in the same automotive design. The cabs of the E14 – E20 and Xi10 – Xi20 feature equipment such as a 3.5-inch full-graphic display. The spacious headroom in the operator’s cab helps to provide additional comfort.

Safety: Top protection in every situation

Protection of the operator and the goods being transported is the top priority for the E14 – E20 and Xi10 – Xi20. Design elements and intelligent assistance systems ensure optimum protection of the operator, the load and the environment. The slim mast profiles, the narrow A-pillar and the low front plate ensure excellent all-round visibility. A strut-free roof pane made of armoured glass is available as an optional extra and this provides a clear view when accessing high shelving.

The low centre of gravity, the overhead tilt cylinders and the torsion-resistant mast construction ensure maximum tilt safety. The forklift trucks are equipped as standard with Linde Curve Assist for automatic speed adjustment when cornering and Linde Load Assist to limit mast inclination and lifting movement. Additional optional assistance systems such as Linde Safety Pilot or Linde Reverse Assist Radar help to further increase safety.

Connectivity: Seamless integration and maximum availability

The E14 – E20 and Xi10 – Xi20 can be seamlessly integrated into digital processes. Thanks to their modern electrical/electronic system architecture and sophisticated sensors, the trucks can be easily connected to warehouse management systems, control systems, fleet management systems and service applications. An optional (E14 – E20) or standard (Xi10 – Xi20) data transmission unit enables the wireless transmission of key truck data such as operating hours or error codes.

Recording error codes helps to ensure any wear or damage is detected at an early stage, which guarantees high truck availability. Software updates and new functions can be installed remotely without the need for a service technician on site. At the same time, fleet managers and service technicians can access and analyse important parameters and performance data at any time.

Service: Robust and low-maintenance for minimal costs

Their tough construction means that the E14 – E20 and Xi10 – Xi20 are designed for high availability and low service costs. The drive axle, electric motors and power inverter are fully encapsulated and are therefore protected from dust and water, and are completely maintenance-free. All components that require servicing are easily accessible to technicians, which speeds up maintenance work.

A hinged battery cover also simplifies the daily inspection of the lead-acid battery (E14 – E20 only). The wireless transmission of truck data helps to optimise service processes and avoid unnecessary downtime. An overall inspection is only required after 1,000 operating hours, and the change of hydraulic oil and hydraulic oil filter is only required after three years (about 6,000 hours).

Tried and tested: Phenomenally powerful and cost-effective

The E14 – E20 and Xi10 – Xi20 showed their superiority in direct comparison with leading competitor models. A performance test certified by TÜV NORD, in which 56 pallets have to be unloaded from a truck, evaluates unloading time, energy costs and overall costs per unloading operation. The energy costs were based on average prices of EUR 0.30 per kilowatt hour (kWh) of electricity. The overall costs compared include the purchase price, personnel costs, energy costs and service costs. The Linde models achieve significantly better results than the competition in all three categories.

-

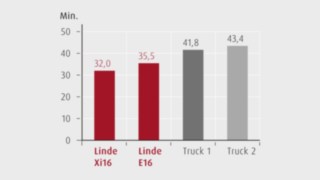

Time required per truck unloading operation

-

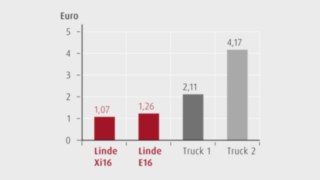

Energy costs per truck unloading operation

-

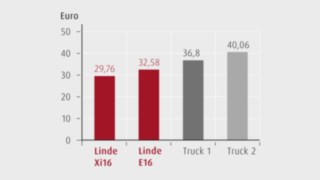

Overall costs per truck unloading operation

Time required per truck unloading operation

- 56 pallets per truckload

Energy costs per truck unloading operation

- 56 pallets per truckload

- Average kilowatt-hour price of EUR 0.30

Overall costs per truck unloading operation

- Purchase price plus personnel, energy and service costs