The assistance system that detects hazards before they arise

Linde Safety Guard

Safety when it matters most

What if people, industrial trucks and the infrastructure could communicate with each other?

Wherever industrial trucks are in use, a complex interplay between man and machine exists. The Linde Safety Guard is an innovative monitoring system which provides an early warning of potential hazards.

Wherever industrial trucks are in use, a complex interplay between man and machine exists. The Linde Safety Guard is an innovative monitoring system which provides an early warning of potential hazards.

Material handling operations like loading and unloading trucks can encounter potentially hazardous situations. Industrial trucks and staff working together in close proximity can be challenging and difficult to control. In the worst-case scenario, this can lead to injury or property damage.

Every aspect of any material handling application demands constant vigilance by all personnel involved: blind corners, low visibility areas and distracting noises are all ever-present safety risks in intralogistics and manufacturing working environments.

A timely warning: the Linde Safety Guard

Linde Safety Guard is an innovative assistance system which increases safety for both truck operators and pedestrians in the vicinity of the truck. Active alarms triggered in the event of a hazard mean that everyone involved can react immediately. Depending on the application and the equipment, the Safety Guard system warns of imminent danger through acoustic warnings, flashing LED lights or vibrations. Hazards can then be dealt with before any physical injury or collateral damage occurs.

This unique safety system was developed by the start-up Comnovo, which was acquired by Linde Material Handling in July 2017. The system has been incorporated into Linde Material Handling’s industrial trucks since early 2016. Since then, the system has proven itself across a wide variety of industries.

always in the safe zone

Be it excessive speeds, staff members crossing a truck’s path or low visibility: there are a multitude of reasons why accidents can occur while working with industrial trucks. The Linde Safety Guard’s system can be configured to monitor specific risks.

Wearable safety: the Pedestrian Warning Band from Linde

The Pedestrian Warning Band is the latest innovation in the Linde Safety Guard System. It uses vibration, sound and light signals to warn its wearer of an approaching truck, ensuring safety during operations. With an accuracy of 10 cm and its ergonomic design, the Pedestrian Warning Band combines high safety with high wearing comfort. The Pedestrian Warning Band fits comfortably over certified high-visibility vests and is equipped with an intuitively replaceable battery. This allows it to be used in all environments, including multi-shift operations.

Tailored safety

The Linde Safety Guard system increases the safety of all staff involved in internal traffic. It can see around corners and through walls, reduces speed automatically and can be programmed to suit any hazardous scenario.

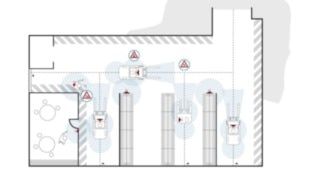

The Linde Safety Guard uses warning zones to prevent accidents. Transmitters are positioned on industrial trucks, walls, racking and even carried by the personnel themselves. This ensures rapid detection, early warning and avoidance of hazardous situations.

If a pedestrian and a truck look likely to collide, then both the industrial truck and the pedestrian are warned simultaneously. A receiver in the truck indicates how many pedestrian staff are approaching the danger zone and from which direction. The pedestrian is warned by the receiver. This also works through walls and racking.

Speed restriction zones can also be pre-defined and programmed, so that the system automatically reduces the truck’s speed in these zones and also warns the truck operator. This minimises accidents between trucks and personnel in areas like production, order picking areas and busy intersections.

All this is only possible because the Linde Safety Guard system is able to precisely determine the position of marked objects or personnel with an accuracy of 10 centimetres and the warning zones are individually adjustable. This level of precision also helps to prevent false alarms. Moreover, a broadband radio signal in the 4 GHz range (UWB) helps to ensure reliability by eliminating interference from WiFi, Bluetooth or RFID.

The system can be adapted to meet any safety requirements. It consists of individual modules and can be tailored to the respective hazardous situation on individual sites.

Benefits at a glance

- Staff and zone recognition

- Warning zones that can be configured within 10 centimetres of precision

- Visualisation of the number and position of staff in the danger zone

- Mutual warning for pedestrian staff and truck operators

- Detection through walls and racking*

- Versatile, adaptable and rapid installation

*Valid for typical infrastructure in intralogistics. Checked during consultation.

-

Truck Unit

-

Portable Unit

-

Sensors

-

Truck Unit small

-

Static Unit

-

Zone Marker

-

Charger

-

Pedestrian Warning Band

Truck Unit

The Tuck Unit warns the operator with LED lights and acoustic signals.

Portable Unit

The Portable Unit warns personnel of approaching industrial trucks using acoustic signals, LED lights and vibration.

Sensors

Detect the modules carried by pedestrians and industrial trucks in the defined hazardous zones.

Truck Unit small

The Truck Unit small is attached to the forklift and communicates with stationary modules such as the Static Unit or the Zone Marker.

Static Unit

The Static Unit marks hazardous zones in critical areas such as access doors or low visibility intersections. This module warns others in the area via acoustic signals and LED lights.

Zone Marker

The Zone Marker defines speed restriction areas.

Charger

The charger charges the Portable Unit inductively. The fully automatic activation provides optimum convenience for the operator.

Pedestrian Warning Band

In the event of danger, the Warning Band warns the pedestrians and the forklift operators. Light and sound signals alert the band carrier about approaching trucks. The ergonomic design is extremely comfortable.

Testimonials

And action: Linde Safety Guard in use

Smurfit Kappa LithoPac in Nybro, Sweden, specialises in offset printed corrugated packaging. They are one of the leading manufacturers of paper-based packaging in the world. At their plant in Nybro, forklifts and people work together closely at a rapid pace. Safety is a high priority. In 2021, Smurfit Kappa LithoPac implemented the Linde Safety Guard. The system was fully adapted to the individual needs of the business and will be expanded even further in the future.